Key Features & Benefits

- No heat required – ideal for chocolate & soft candy

Cold-seal adhesive is activated by pressure only, so there is no thermal shock to chocolate coatings, fillings or delicate inclusions. This helps maintain product shape, gloss and bite. - High packaging speed & line efficiency

By eliminating the heating and cooling steps of conventional sealing, cold-seal film enables higher running speeds and shorter cycle times, improving overall line efficiency. - Excellent moisture & oxygen barrier

Laminated structures with BOPP, PET, metallized films or aluminum foil provide reliable barrier protection, extending shelf life and preserving flavor and texture. - Consistent sealing performance

The cold-seal coating is applied in a precise pattern, giving strong, repeatable seal strength on modern wrapping machines while minimizing blocking and unwanted adhesion in the roll. - Custom printing for strong shelf appeal

Up to 8–10 color printing with glossy, matte or combined effects is available. Designs are printed within the laminate to protect the artwork from scuffing on the line and in distribution. - Suitable for a wide range of confectionery formats

One solution for chocolate bars, energy bars, wafers, nougat, toffees, gummy candies and more, helping you standardize packaging materials across different SKUs. - Optional recyclable or eco-friendly structures

For brands targeting sustainable packaging, we can recommend recyclable or lower-impact structures while keeping the required barrier and machine performance.

Typical Applications

Our chocolate & candy cold-sealing film is commonly used for:

- Chocolate bars and coated wafers

- Filled bars (caramel, nougat, protein bars, cereal bars)

- Toffees, soft caramels and chewy candies

- Hard candies and lollipops

- Gummies and jelly sweets

- Other flow-wrapped confectionery and snack products

Compatible with:

- Horizontal flow-wrap machines

- HFFS bar wrapping lines

- Other cold-seal capable automatic packaging equipment

Material Structures & Options

We select or design the film structure according to your product, required shelf life and packaging machine:

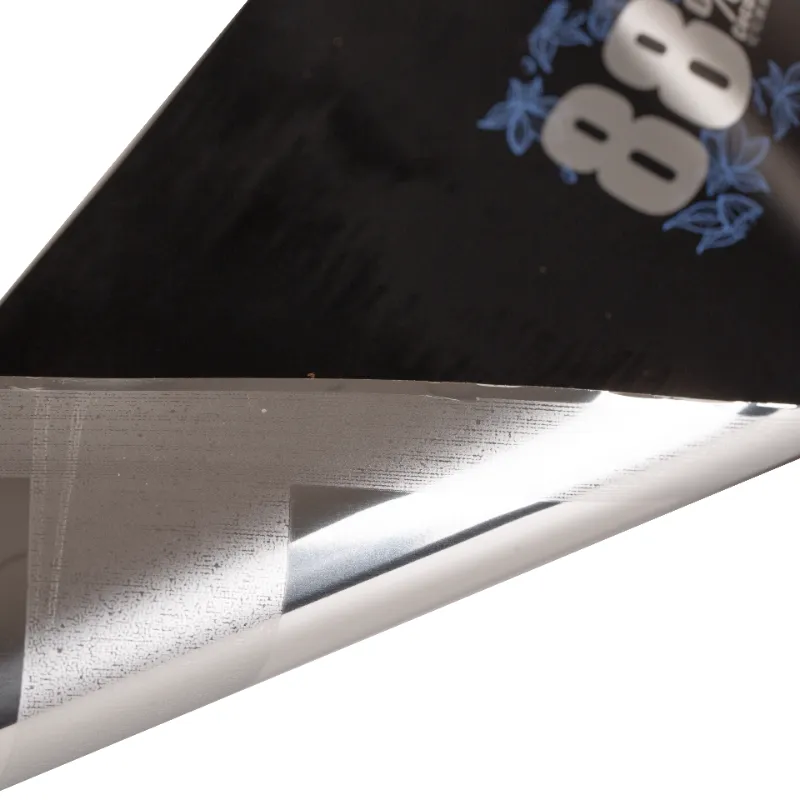

- BOPP / BOPP or BOPP / CPP – standard clear or matte structures for many confectionery products

- PET / BOPP / cold-seal – for higher stiffness and print quality

- BOPP / VMCPP or PET / VMPET / PE – improved barrier against oxygen and moisture for sensitive chocolate and bars

- Aluminized cold-seal films – for superior light and aroma barrier where needed

Surface finishes:

- High-gloss, matte or registered matte

- Metallic effects and special varnishes for premium brands

Cold-seal coating:

- Pattern-applied cohesive coating on the inner side

- Coating weight adjusted to machine speed and desired seal strength

Technical Specifications (Customizable)

We can match your existing film or recommend a specification based on your machine and product:

- Film thickness: typically 30–80 μm for chocolate & candy flow-wrap film

- Roll width: customized to suit your product size and forming set

- Core diameter: usually 3" or 6"

- Roll length: optimized for your line speed and changeover plan

- Printing: up to 8–10 colors, front and back, with registration to the cold-seal pattern

- COF (coefficient of friction): tailored to your machine requirements to ensure smooth running

If you already use a cold-seal film from another supplier, we can work from your current specification or sample roll to provide an equivalent or optimized structure.

Quality & Compliance

- Produced in Zhejiang, China by WanLe Package, a professional manufacturer of food and coffee packaging films and pouches.

- Food-grade materials and inks

- Strict in-house quality control to ensure consistent roll profile, coating weight and print quality

- Compliance with relevant food-contact standards can be confirmed according to your destination market (e.g. EU, North America, etc.)

Packaging & Supply

- Supplied as printed or unprinted roll film on 3" or 6" cores

- Rolls are wrapped to protect from dust and moisture during transport

- Export-ready packaging suitable for sea or air shipment

- Sample rolls available for machine testing before mass production

What Information We Need for a Quick Quote

To offer the best structure and pricing for your chocolate or candy application, please include:

- Product type: chocolate bar, wafer, filled bar, gummies, toffees, etc.

- Wrapping style & machine: flow wrap / HFFS; brand and model if possible.

- Product dimensions & target pack size: bar length, width and thickness.

- Shelf life & storage conditions: ambient, refrigerated or special conditions.

- Printing requirements: number of designs, number of colors, matte/gloss effects.

- Barrier level: standard, high barrier or light-blocking requirements.

- Order quantity: trial order and estimated annual usage.

- Destination country/port: for logistics and compliance reference.