Packaging materials and storage conditions are key factors affecting the shelf life of pet food. High-quality packaging materials effectively block air, moisture, and microorganisms, thereby extending the product's shelf life. Appropriate storage environments (such as cool, dry conditions away from direct sunlight) also help maintain food quality.

1. Types and Functional Characteristics of Packaging Materials

① Physical Barrier Properties

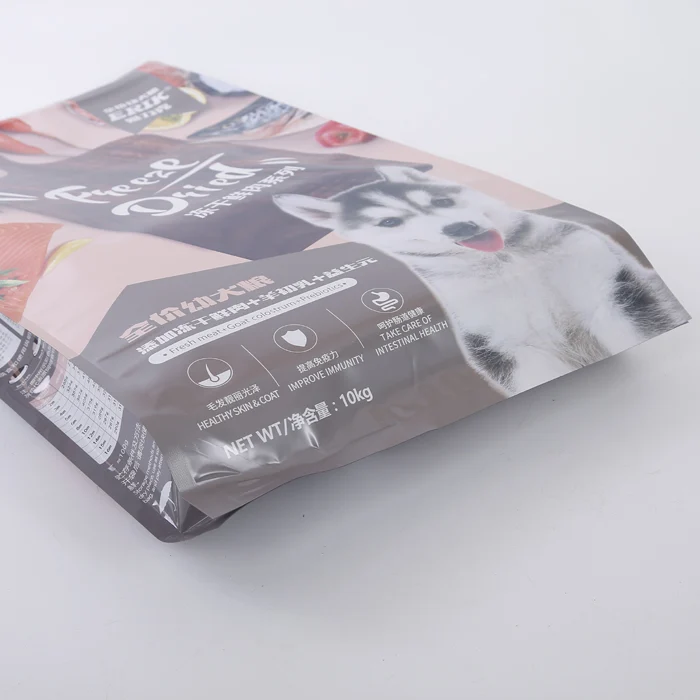

Composite Packaging Films (e.g., PET/AL/PE): The aluminum foil layer provides excellent oxygen barrier properties (oxygen transmission rate <0.5 cm³/m²·24h), preventing lipid oxidation (e.g., fish oil, chicken meal) and vitamin loss. Suitable for high-fat, high-protein pet foods (e.g., cat food, dog food).

Vapor-Deposited Metalized Polyethylene (VMPET): Lower cost than pure aluminum foil with slightly reduced barrier properties, yet sufficient for moisture protection in standard pet foods (e.g., dry kibble).

Nylon (PA) Composite Film: High puncture resistance, suitable for pet foods containing bone fragments or hard particles to prevent packaging damage.

② Chemical Stability

Material Migration Risk: Plasticizers in plastics (e.g., DEHP) may migrate into food. Compliance with EU Regulation EC No. 10/2011 or FDA 21 CFR 177.1630 is required. Food-grade polyethylene (PE) or polypropylene (PP) is recommended for inner-layer materials.

Antimicrobial Coating: Silver ion coatings inhibit microorganisms like E. coli and Salmonella, extending shelf life (e.g., inner coatings in wet food cans).

2. Impact of Packaging Processes on Shelf Life

Sealing Technology: Heat seal strength must be ≥1.5 N/15mm to prevent oxygen ingress (e.g., vacuum-packed dog food). Ultrasonic sealing is suitable for multilayer composite films, minimizing heat damage.

Nitrogen Flushing: Nitrogen replacement rate must exceed 99% to inhibit aerobic bacteria (e.g., mold) growth and extend wet food shelf life (e.g., cans, pouches).

3. Packaging Innovation Technologies

①Active Packaging

Oxygen Absorbers (e.g., iron powder packets): Reduce internal oxygen concentration below 0.1%, suitable for high-fat wet foods.

Humidity Regulators (e.g., molecular sieves): Maintain internal humidity between 30%-50% to prevent dry food clumping.

② Smart Packaging:

Time-Temperature Indicators (TTI): Display cumulative temperature exposure through color changes, warning of spoilage risks (e.g., freeze-dried foods in cold chain transport).

Impact of Storage Conditions on Shelf Life

1. Core Role of Temperature in Shelf Life

High temperatures accelerate spoilage: Every 10°C increase in temperature accelerates lipid oxidation by 2-3 times (e.g., fish oil oxidizes 4 times faster at 30°C than at 20°C).

Recommended storage temperatures: Dry food <25°C, wet food <10°C.

Low temperatures inhibit microbes: Freezing (below -18°C) completely suppresses bacterial growth, but avoid repeated freeze-thaw cycles to prevent protein denaturation (e.g., freeze-dried raw meat and bones).

2. Effect of Humidity on Shelf Life

Hygroscopic foods: Dry food water activity (Aw) must be <0.6 to prevent mold growth (e.g., Aspergillus). High humidity (RH>70%) reduces dry food shelf life by over 50%.

Humidity control recommendations: Use desiccants (e.g., silica gel packets) or dehumidifiers to maintain storage humidity <60%.

3. Impact of Light Exposure on Shelf Life

Photooxidation: Vitamins A and E degrade under UV light; they require light-blocking packaging (e.g., foil pouches).

4. Impact of Oxygen Concentration on Shelf Life

Aerobic bacteria (e.g., molds): Growth inhibited at oxygen concentrations <0.5%.

Anaerobic bacteria (e.g., Clostridium botulinum): Require vacuum packaging or nitrogen-flushed packaging for inhibition.

5. Comprehensive Storage Condition Management

Cold Chain Logistics: Maintain -18°C ± 2°C during freeze-dried food transport to prevent ice crystal damage from temperature fluctuations.

Stacking Method: Limit pallet stacking height to ≤1.8 meters to prevent leakage from deformation of bottom-layer packaging under pressure.

| Pet Food Types | Packaging Materials | Storage Conditions | Shelf Life Extension Mechanism |

| Dry Food | Aluminized PET + Desiccant | Room Temperature, Light-Avoiding (RH < 60%) | Aluminized layer blocks oxygen; desiccant maintains low humidity |

| Wet Food Cans | Tinplate Can + Epoxy Resin Coating | Refrigerated (2-8°C) | Metal can block oxygen; low temperature inhibits microorganisms |

| Freeze-Dried Raw Meat & Bones | Aluminum Foil Bag + One-Way Valve | -18°C frozen storage Cool | Aluminum foil blocks oxygen; the vent valve releases CO₂ |

| Snacks (Chicken Strips) | Kraft Paper Laminated with PE Film | shaded room temperature | PE film blocks fat oxidation; kraft paper provides strength |

Methods for Determining Shelf Life

Reference Method and Literature Method: Estimate shelf life by comparing with similar products in the market and considering the company's specific conditions. After product launch, validate shelf life through scientific testing and adjust as necessary.

Experimental Method:

Long-Term Stability Testing: Simulate actual storage, transportation, sales, and consumption conditions to evaluate test indicators, identify degradation patterns, and determine deterioration endpoints.

Accelerated Degradation Testing: Expose samples to conditions exceeding normal levels to accelerate deterioration beyond standard timelines, thereby projecting shelf life under anticipated storage conditions.

Wanle Package specializes in producing various high-quality pet food packaging bags. Contact us now to enjoy excellent service and customized solutions!